Tachion Electricals and Controls Pvt Ltd. specializes in delivering cutting-edge Fuel Polishing Systems designed to maintain the quality and purity of stored fuel within Data Center facilities across India. Our systems, available in manual, semi-automatic, and fully automatic versions with various capacities, guarantee the preservation of fuel integrity for extended durations.

Fuel polishing stands as the pinnacle of technical cleaning processes, meticulously removing water and particulate matter from stored fuel intended for medium to long-term usage. This process safeguards fuel quality, effectively mitigating potential engine and generator failures stemming from fuel-related issues. The multi-stage process methodically eliminates water, sludge, microbial contaminants, and other impurities, adhering to a specific sequence to ensure optimal fuel condition. Utilizing a progressive filtration and conditioning approach, our system adheres to ISO 4406 standards, employing compatible filter elements from renowned brands like Parker Racor, Velcon, and PECO.

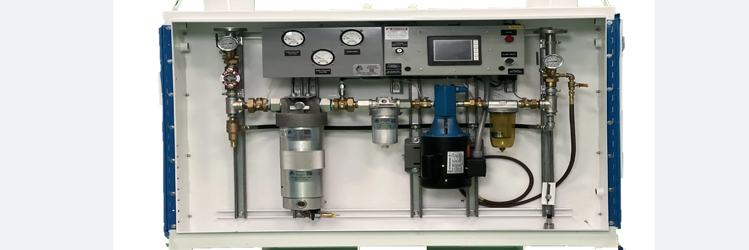

Outdoor, weatherproof, pad-mountable enclosure for seamless outdoor installation. Flameproof Motor & Flameproof integrated control panel ensuring utmost safety. Inlet and outlet ball-type shutoff valves for optimal control. Pressure differential gauges and switch filters to monitor filter life. High water detector switches for enhanced safety measures. Optional circulation pump (50-1000 LPM) for tailored functionality.

Parker-Racor make filtration components ensuring superior efficiency. Y-Strainer (40 S.S. mesh) for 100-micron cleanable filtering. Cleanable type media pre-filters (25 microns) for prolonged use. Replaceable cartridge-based final filter-water separator (10 microns) for precision.

Leak detection sensors integrated within the system. High-quality sensors facilitating secure operation interlocks. Water in Fuel (WIF) sensor adept at detecting separated water in filter housing. Customizable unit support catering to individual site requirements.

Intuitive touch screen technology providing graphical representation and ease of use. Fully programmable control system adaptable to specific operational requirements while offering comprehensive monitoring information.

BMS-compatible control panel enabling local and remote monitoring and management.

The Tachion Fuel Polishing System is a permanent installation meticulously engineered to automatically filter and cleanse stored fuel, guaranteeing optimal performance, and mitigating the risks associated with contaminated fuel. Ensure uninterrupted operations and longevity of your equipment with our state-of-the-art Fuel Polishing Unit.

Note: Diesel fuel stored in bulk tanks over time may deteriorate, leading to contamination by water, solids, and bacterial growth. Our system provides a solution to maintain and enhance fuel quality, preventing power output reduction, system failures, and costly repairs.